TY-DECK POLYURETHANE MODULAR SCREEN MEDIA – UNBEATABLE DELIVERY TIME

DELIVERY IN JUST TWO WEEKS – ANY REQUIRED OPENING, EVERY SUCCESS!

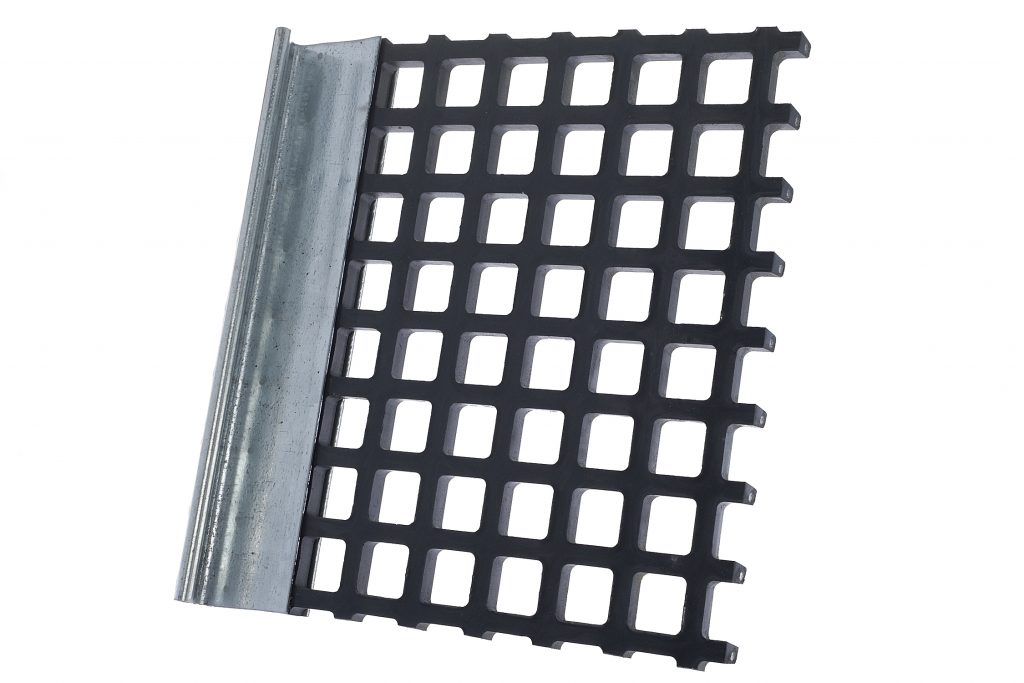

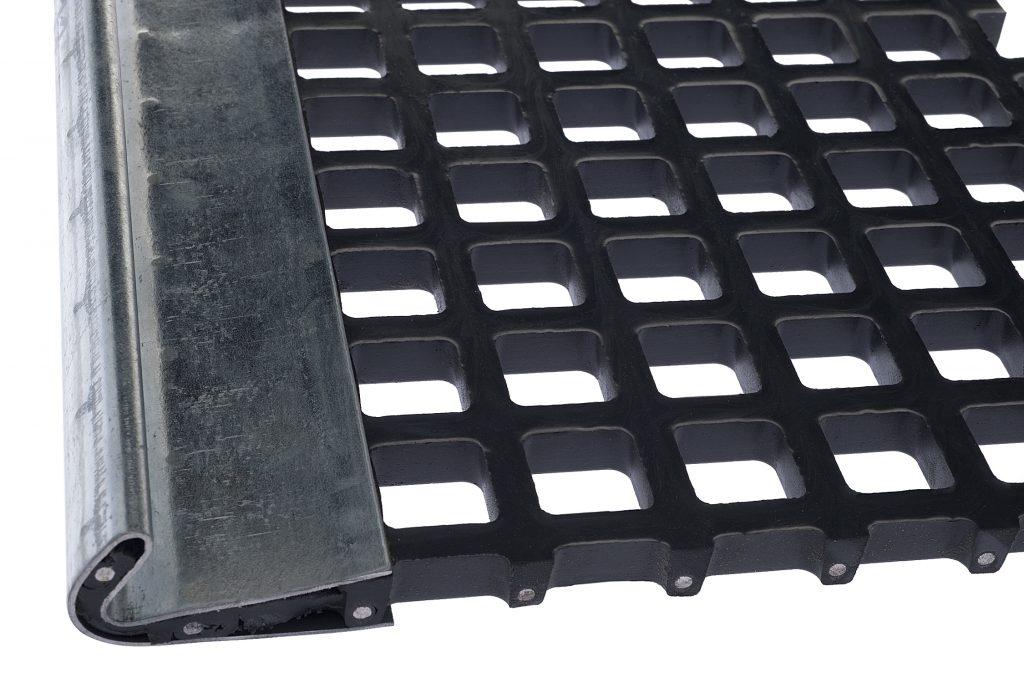

The inhouse produced Ty-Deck modular panels are poured open cast and permanently harden when cured to maintain the chemical properties required to resist wear.

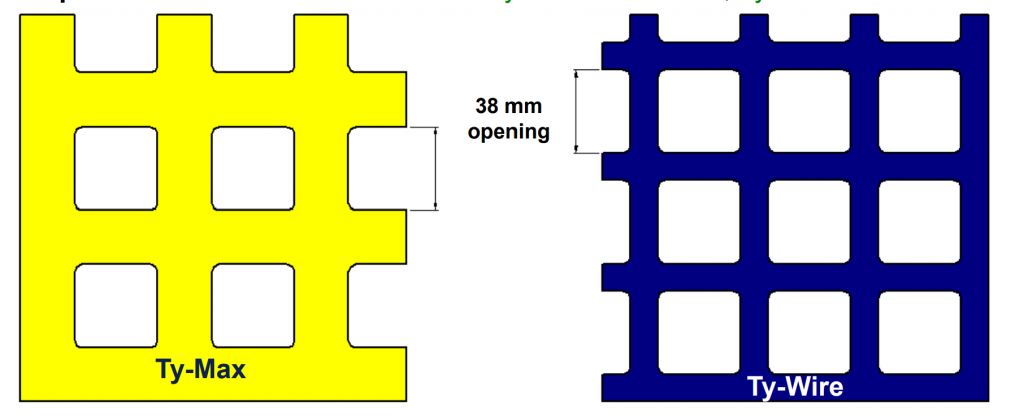

available in 300 mm x 1000 mm / 300 mm x 500 mm & other customized sizes I 30 & 40 mm thickness

Features

- 1 – 2 longer lifetime than injection moulded panels

- Lightweight modular design enables easy installation

- Resistant to heavy loads in wet and dry applications

- Reduce noise pollution

- Available in the most modular hold-down systems

- Achieve excellent results in various applications from sand and gravel to coal and ironworks materials

- customized openings available in the widths:

- available in 300 mm x 1000 mm / 300 mm x 500 mm & other

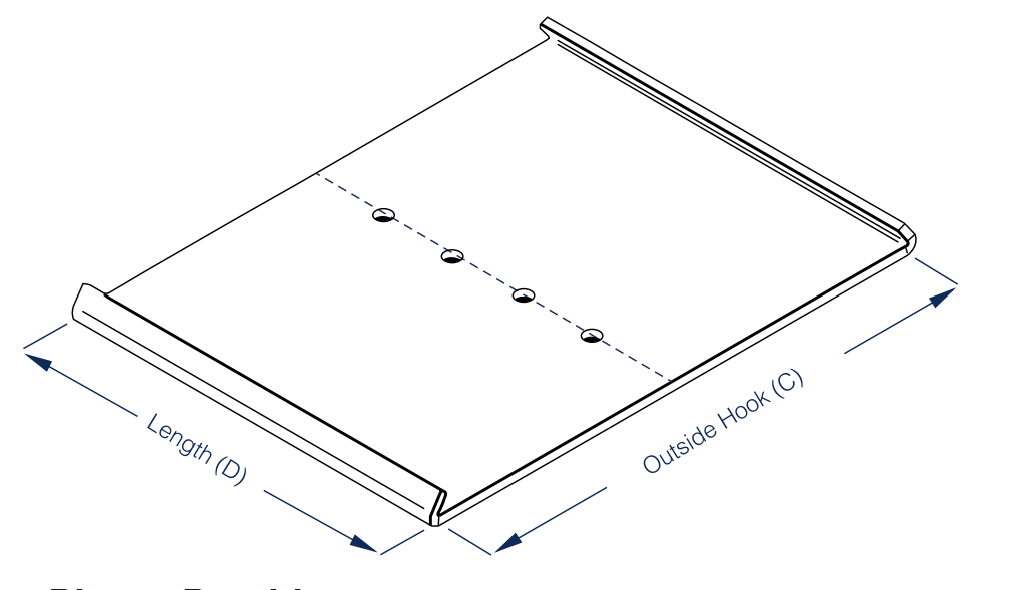

Technically Details

| Top Size | Cut size range | Slot |

| up to 12” (30mm) depending on the application and tonnage | customized openings available Smallest 1.2 mm Largest 4” (120mm) | Largest 1-5/8” X 1-3/4” (25mm X 25mm) |

The Niagara TY Deck WS85

Easy installation I different hold-down systems I any required opening I 2 weeks delivery time I 30 & 40 mm thickness

Your Benefits are Ensured

• Lasts 1-1/2 to 2X longer than injection molded polyurethane screen media.

• Lightweight, modular design makes for easy installation and allows individual panels to be replaced as required.

• Available in multiple hold down systems depending on your deck setup.

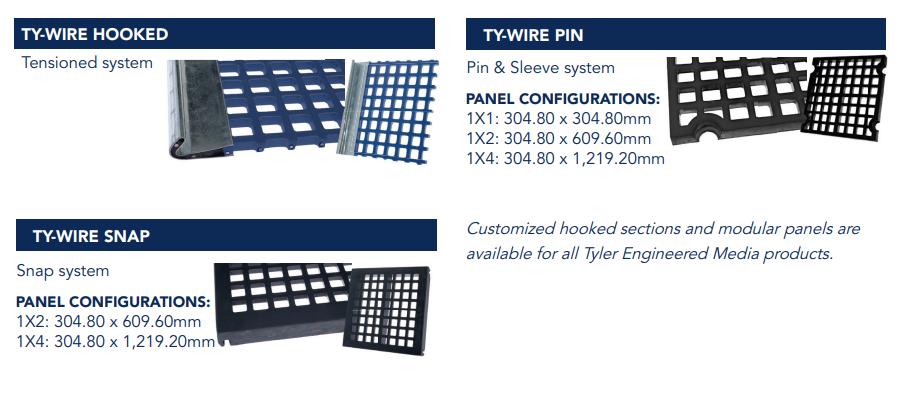

Hold-Down Systems

• Ty-Deck Snap panels provide snap-in installation

• Ty-Deck Pin panels are available for pin-and-sleeve installation

• Ty-Deck Groove panels provide tongue-and-groove installation

• Ty-Deck Bolt panels offer bolt-down installation

The experts notes

“Many mine operators and producers prefer the wear life of modular screen media, but think that this comes with a high sacrifice in open area. With Pro-Deck, different style screen panels are blended in a way that both wear life and open area are optimized. Our focus with this breakthrough upgrade was to address the pressing needs of our customers,” said Oliver Kunz, the esteemed screen media expert at Haver & Boecker Niagara Oliver Kunz. “By shortening the delivery time for NIAGARA TY DECK POLYURETHANE MODULAR SCREEN MEDIA to just two weeks, we are empowering our clients to operate with unmatched efficiency and flexibility, thereby driving productivity and profitability to new heights and preventing the unexpected downtime of their operation.”

Learn more

More about Haver & Boecker Screen Media +

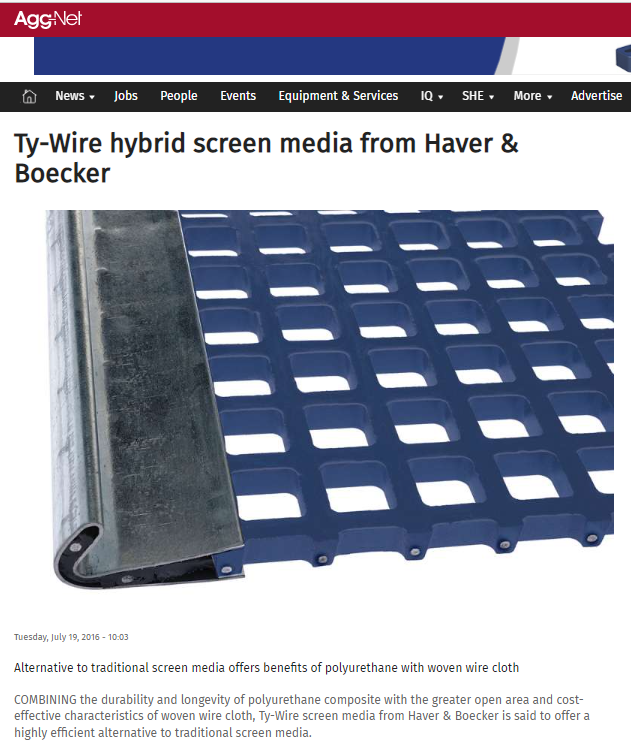

You want to achieve an optimal screening result? At Haver & Boecker Niagara we manufacture all types of screen media in-house providing our customers with polyurethane, industrial, hybrid, self-cleaning and rubber screen media. The wide range of screen media is specially adapted to your requirements – to optimize your vibrating screens we use the consultative approach, using the most effective type of screen for each sieving phase. We analyze the screening phases and combine and integrate the screening media with the only aim – to increase your efficiency!

YOUR BENEFITS ARE INSURED

Do you know that using the right screen media can optimize your reprocessing process? We, at Haver and Boecker Niagara, offer a wide range of screening media to meet any screening requirement profile. Contact us and get all the benefits you need:

- Achieve long service life

- Achieve screen quality

- Minimize clogging

- Minimize downtime

- Reduce noise pollution

After selection and tailored to your needs, the final installation of the new screen media is technically flawless, in perfect quality and with the goal of creating added value for you!

Haver & Boecker Niagara screening media are adaptable to all environments and tasks and designed to offer maximum productivity without compromising quality. By partnering with Haver & Boecker Niagara, you get the widest selection of reliable screening media solutions from a single source.

Your Guide to Optimal Screening +

Haver & Boecker Niagara Screen Media Portfolio +

More about Tyler Engineered Media on a video +

TY Deck Polyurethane Modular Screen Media WS85 sounds interesting to you? Try it now!