TY Plate Perforated Plate Modular Screen Media

On Stock

-

Fast Delivery

-

Best Quality

-

Good Price

description

TY Plate Perforated Plate Modular Screen Media

Ty-Plate offers high wear resistance in square, round, hexagonal and slotted openings, available in both hooked sections and modular panels, so there’s no deck conversion required. Ty-Plate can be custom made with in-line or staggered openings, and blank areas can be incorporated to handle feed and protect rails. Its tapered openings prevent pegging. Try it now!

Features

- Low wear and tear and toughness

- Square, slotted and round openings available

- Offset perforation possible

- Available in a hardness of 165 to 500 Brinell

- Available as hooked system and module variant

- Material thickness depending on the application

Technically Details

| Top Size | Cut size range | Slot |

| Up to 18” (460mm) depending on the application and tonnage. | Square, round and hexagonal openings available. • Square Openings: from 7/16” • Round Openings: from 7/16” • Hexagonal Openings: from 7/16” | Slotted Openings: available upon request |

TY Plate

Your screen media in different manufacturing forms

Your Benefits are Ensured

- Wear-resistant steel alloys maximize screen life.

- Design offers full clearance from the top to the bottom of the screen with minimal risk of blinding.

- Tapered openings reduce pegging.

Application

- Use where high open area is required

- Effective against pegging

- Abrasive materials

Options

Specialty Steels

Heat treated and abrasion resistant specialty steels provide

extra durability.

Crown

Panel can be formed to suit crown on deck.

Rubber Facing

Provides significant abrasion resistance, allowing a longer life.

Ty-Plate screen sections are formulated to provide longer screen life and higher open area than

conventional perforated plate.

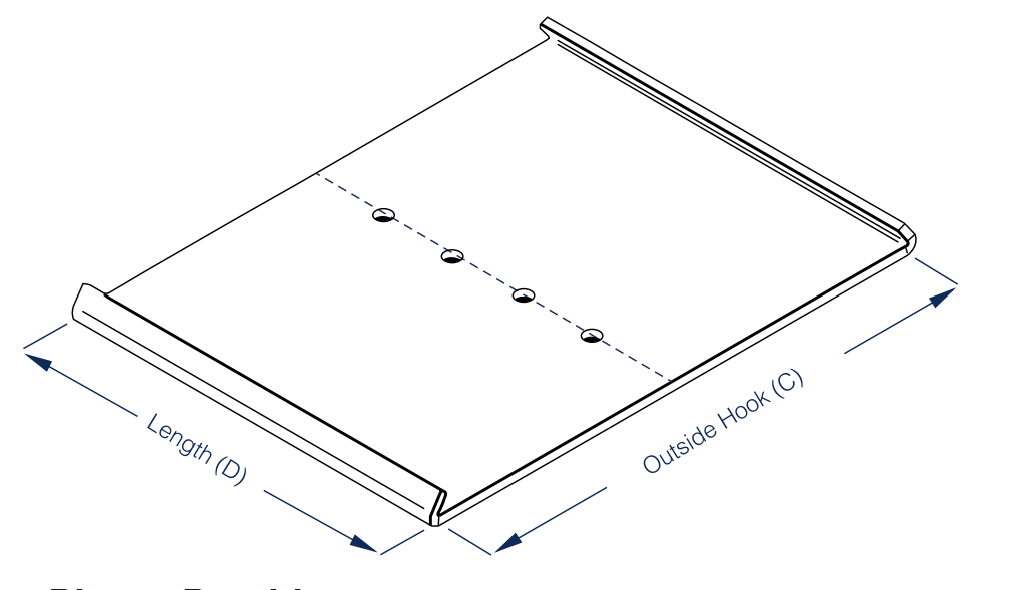

For the Perfect Fit

Please Provide:

A – Side Tensioned or End Tensioned

B – Hook Direction (2 Hooks Up / 2 Hooks Down or 1

Hook Up and 1 Hook Down)

C – Width – Measurement from the outside of one

hook to the outside of the other hook

D – Length – Measurement of the length of the hook

E – Hook Type

F – Hole Size and Spacing

The heavy-duty Niagara TY-Plate screen media for reduced pegging

Heavy-duty Ty-Plate panels are engineered with wear-resistant steel alloys for highly abrasive applications. They feature tapered openings, in square, round, hexagonal and slotted configurations, to reduce pegging. The screen media can be custom made with in-line or staggered holes, and blank areas can be incorporated to handle feed and protect rails.

You want to learn more?

Download the Niagara TY Plate Brochure now!

Learn more

More about Haver & Boecker Screen Media +

You want to achieve an optimal screening result? At Haver & Boecker Niagara we manufacture all types of screen media in-house providing our customers with polyurethane, industrial, hybrid, self-cleaning and rubber screen media. The wide range of screen media is specially adapted to your requirements – to optimize your vibrating screens we use the consultative approach, using the most effective type of screen for each sieving phase. We analyze the screening phases and combine and integrate the screening media with the only aim – to increase your efficiency!

YOUR BENEFITS ARE INSURED

Do you know that using the right screen media can optimize your reprocessing process? We, at Haver and Boecker Niagara, offer a wide range of screening media to meet any screening requirement profile. Contact us and get all the benefits you need:

- Achieve long service life

- Achieve screen quality

- Minimize clogging

- Minimize downtime

- Reduce noise pollution

After selection and tailored to your needs, the final installation of the new screen media is technically flawless, in perfect quality and with the goal of creating added value for you!

Haver & Boecker Niagara screening media are adaptable to all environments and tasks and designed to offer maximum productivity without compromising quality. By partnering with Haver & Boecker Niagara, you get the widest selection of reliable screening media solutions from a single source.

Your Guide to Optimal Screening +

Haver & Boecker Niagara Screen Media Portfolio +

More about Tyler Engineered Media on a video +

TY Plate Screen Media sounds interesting to you? Try it now!