TY MAX Polyurethane Screen Media

On Stock

-

Fast Delivery

-

Best Quality

-

Good Price

description

TY MAX Polyurethane Screen Media

Ty-Max hooked screen media offers the wear life of a polyurethane panel in a hooked section, so no deck conversion is required. Ty-Max sections are manufactured using a specially formulated polyurethane developed for optimum wear resistance.

Features

- 7 – 9 longer lifetime than woven wire

- Can be installed like wire mesh, no deck conversion

- and additional hardware required

- Excellent wear resistance and impact elasticity

- Resistant to heavy loads in wet and dry applications

- Tapered openings reduce blinding & pegging

- Reduce noise pollution

- Available in side- or end- tensioned hooks

- Square and slotted openings available

- Available opening widths: Square from 1.2 mm to 100 mm, Rectangular from 0.12 mm x 13 mm to 13mm x 57mm

Technically Details

| Top Size | Cut size range | Slot | Material Temperature Range |

| Up to 12″ (304.80 mm) depending on the application, tonnage, particle size, type, drop height, rail spacing and feed method. | Square and slotted openings available. • Smallest – 3/32″ (2.38 mm) • Largest – 4″ (101.60 mm) | Smallest: 0.50 x 12.00mm Largest: 3/8 x 1″ (9.53 x 25.40mm | Highest – 149º F (65º C) continuously 176º F (80º C) intermittent |

TY Max: Your screen media in different manufacturing forms

Your Benefits are Ensured

- Tapered openings virtually eliminate pegging.

- Standard tensionable hooks eliminate the need for laborious deck conversions.

- Polyurethane composition extends wear life and handles direct feed better than wire cloth, reducing change-outs and maximizing productivity.

Options

Solid Impact Area

Ty-Max can be manufactured without openings in designated areas to reduce wear from high impact.

Center Hold Down

To allow secure fastening at the center of the deck, Ty-Max can be manufactured with a center hold down to secure the section on wide vibrating screens.

Flex Membrane

Specially formulated flex membrane allows for more screening action and reduced issues with blinding.

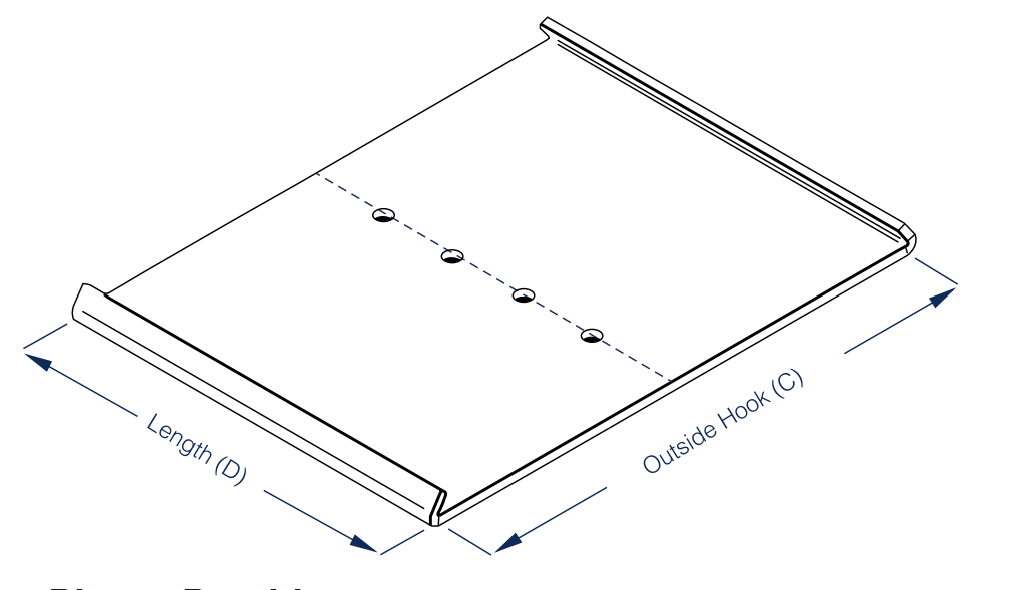

For the Perfect Fit

Please Provide:

A – Side Tensioned or End Tensioned

B – Hook Direction (2 Hooks Up / 2 Hooks Down or 1

Hook Up and 1 Hook Down)

C – Width – Measurement from the outside of one

hook to the outside of the other hook

D – Length – Measurement of the length of the hook

E – Hook Type

F – Hole Size and Spacing

Opening vs. Open Screen Media

Opening: the size of the hole – 38 mm opening on both screens

Open Area: the number of holes – Ty-Max has 4 holes; Ty-Wire has 9 holes

Increasing the open screen area generally reduces the lifetime and reserve. A combination of these panels on the deck is a good compromise between wear and output!

Blending Screen Media

Blending screen media on a single deck helps increase production and extend periods between screen

change-outs. Here we’ve blended two panels of Ty-Max polyurethane on the feed end, with Ty-Wire

hybrid screen media on the remaining sections to maximize wear life and open area.

You want to learn more?

Download the Niagara TY Max Brochure now!

The Niagara Ty-Max hooked for a cambered deck

Ty-Max is poured using open cast technology and permanently hardens when cured to maintain its chemical properties, so it resists wear and tear. The polyurethane also wears exponentially longer than wire cloth and handles direct feed better, maximiz…

Learn more

More about Haver & Boecker Screen Media +

You want to achieve an optimal screening result? At Haver & Boecker Niagara we manufacture all types of screen media in-house providing our customers with polyurethane, industrial, hybrid, self-cleaning and rubber screen media. The wide range of screen media is specially adapted to your requirements – to optimize your vibrating screens we use the consultative approach, using the most effective type of screen for each sieving phase. We analyze the screening phases and combine and integrate the screening media with the only aim – to increase your efficiency!

YOUR BENEFITS ARE INSURED

Do you know that using the right screen media can optimize your reprocessing process? We, at Haver and Boecker Niagara, offer a wide range of screening media to meet any screening requirement profile. Contact us and get all the benefits you need:

- Achieve long service life

- Achieve screen quality

- Minimize clogging

- Minimize downtime

- Reduce noise pollution

After selection and tailored to your needs, the final installation of the new screen media is technically flawless, in perfect quality and with the goal of creating added value for you!

Haver & Boecker Niagara screening media are adaptable to all environments and tasks and designed to offer maximum productivity without compromising quality. By partnering with Haver & Boecker Niagara, you get the widest selection of reliable screening media solutions from a single source.

Your Guide to Optimal Screening +

Haver & Boecker Niagara Screen Media Portfolio +

More about Tyler Engineered Media on a video +

TY Max Polyurethane Screen Media sounds interesting to you? Try it now!