Refurbishment Program

On Stock

-

Fast Delivery

-

Best Quality

-

Good Price

description

Refurbishment Program

Make the old new again – save money

Just because a vibrating screen is showing some wear after years of use doesn’t mean it’s necessarily time for a brand-new piece of equipment. We offer refurbishment services on many of our vibrating screens that includes much more than a fresh coat of paint. Request your refurbishment program now!

What is included?

- Machines can be rebuilt onsite, or at a Haver Service facility, depending on their condition.

- All critical parts are examined to determine if they can be reused, and are documented in a PROcheck Service Report.

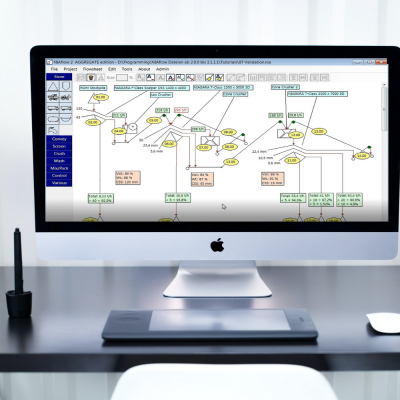

- Pulse vibration analysis is used both prior to the refurbishment for complete machine analysis, as well as after the refurbishment to ensure your machine is running to factory specifications.

OUR PROCESS

4 Simple Steps for Vibrating Screen Efficiency

Our refurbishment program consists of 4 simple steps to help you update outdated and inefficient screening equipment with all the bells and whistles of new technology, at a fraction of the cost of buying new. Upgrade your ols vibrating screen, at nearly half the cost of purchasing a new machine – here’s how it works:.

1. Inspection

First, determine whether to rebuild or replace your screen’s components. A screening specialist will visit your facility and inspect all critical components — giving a recommendation of parts that can be rebuilt or replaced.

2. Upgrade

Following the inspection, work with your manufacturer to install re-engineered parts. Incorporating newer components improves screening performance without the expense of buying new.

4. Testing

Let certified technicians test your refurbished vibrating screen using vibration analysis technology. This ensures all components work like new and that the equipment runs at OEM standards.

5. Engineered Screening Studies

Welcome a technician to visit your facility to evaluate your entire screening process — from start to finish. A complete screening consultation results in a smoother, more efficient — and typically, more profitable — operation.

Rebuild, Refurbish or Buy New?

“The Niagara refurbishment program saves you as much as 40% over buying new, all while having the assurance that your refurbished machines will run at peak performance“

Ready to update your mineral processing equipment rather than buy new?