PULSE CONDITION MONITORING

On Stock

-

Fast Delivery

-

Best Quality

-

Good Price

description

PULSE CONDITION MONITORING

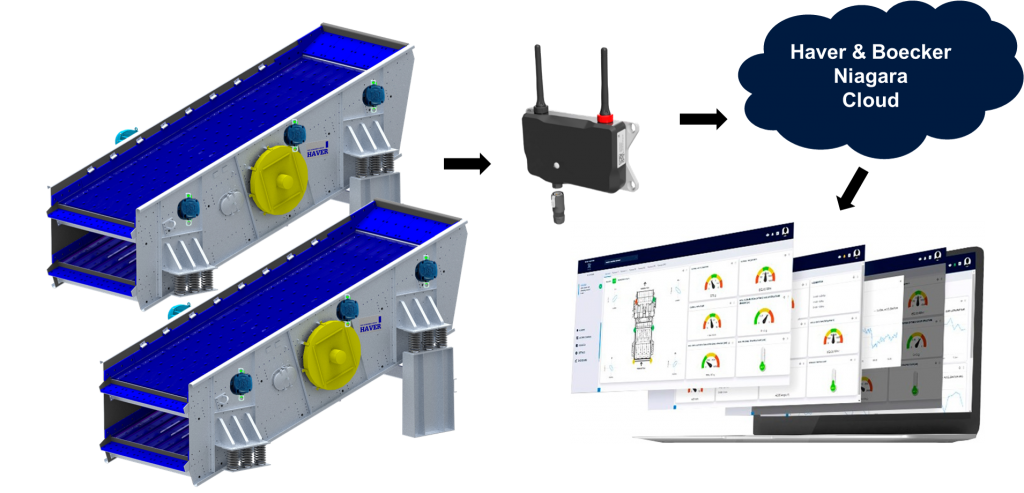

As a leader in vibrating screen technology, Haver & Boecker Niagara developed Pulse Condition Monitoring specifically for monitoring the health of vibrating screens, using modern algorithms to provide accurate measurements and forecasts complemented by information that is easy to understand. Try our Pulse Condition Monitoring now!

WHAT?

Pulse Condition Monitoring (Pulse CM) is the next level in the Pulse portfolio, accompanying Pulse Vibration Analysis.

Similar to Pulse Vibration Analysis, the Pulse CM system analyzes data to help users get the most of their equipment. Unlike Pulse Vibration Analysis, Pulse CM uses predictive data and artificial intelligence to assist with maintenance and production planning, helping to prevent unwanted downtime or even catastrophic failures.

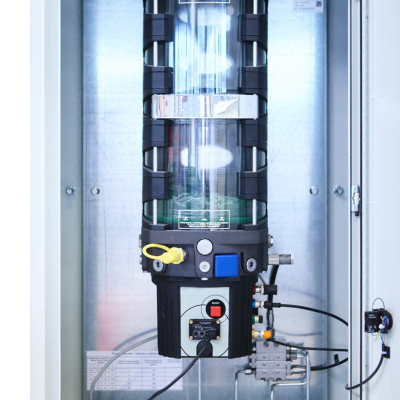

HARDWARE INFO

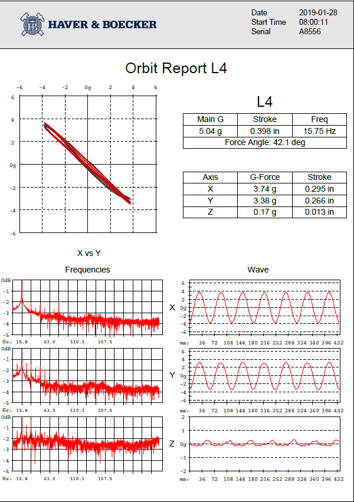

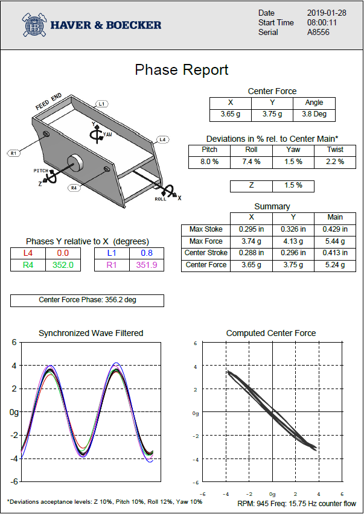

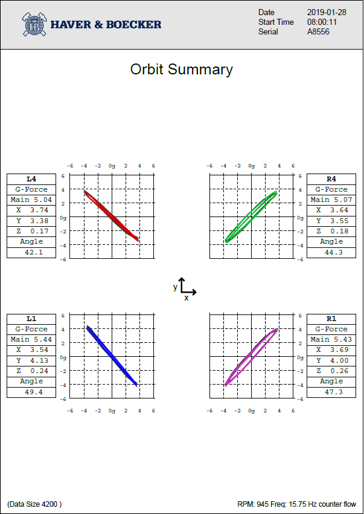

Wireless body sensors applied for

monitoring:

- Global acceleration

- Acceleration on axis X, Y and Z

- Global amplitude

- Displacement on axis X, Y and Z

- Frequency

- Motion orbit

- Phase angle

Wireless bearing sensors applied for

monitoring:

- Temperature

- Power bands

- Peak-to-peak acceleration

- RMS acceleration on axis X, Y and Z

- RMS velocity on axis X, Y and Z

- Crest factor

- Vibration spectrum

The body sensors acquire information each 5 minutes, while the bearing sensors acquire them every minute. After each 12 hours, vibration spectrum information is also available for the bearings. The sensors are especially suitable to both the environment and the equipment, with wireless connections and IP69K degree of protection.

The sensores battery is long lasting, approximately 3 years considering the acquisition intervals mentioned previously. To collect all measured data from the structural and drive components, Pulse CM is equipped with a receptor, that can connect with up to 20 sensors within a radius of up to 75 m. Using a

cellular signal or Wi-Fi from the plant, it will send all data to the Haver & Boecker Niagara Cloud. Part of the collected information will also be made available locally for communication with supervisory software via cable through Profib-us protocol

HOW IT WORKS?

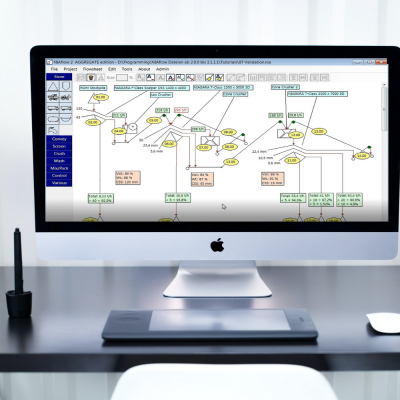

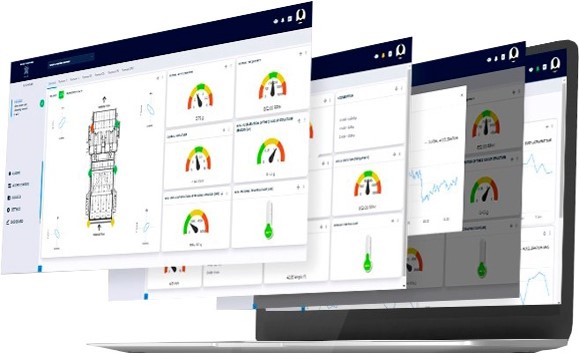

The system captures real time information on monitored equipment and provides alerts via e-mail when it detects the first sign of potential problems. By constantly monitoring the accelerations of the vibration screen, Pulse CM provides a forecast of the equipment’s dynamic condition in future times of 48 hours, 5 days and 4 weeks. The system detects anomalies that will point an operation’s maintenance team to specific areas of the equipment that may require attention. With consistent use, Pulse CM will accurately point out and predict critical issues and advise when to schedule maintenance, along with what to focus on during that planned downtime.

To collect all data from the body and drive components, Pulse CM is equipped with a gateway that can connect with up to 20 wireless sensors, within a radius of up to 246 feet (75 meters). Using a cellular signal or Wi-Fi from the plant, it will send all data to the Haver & Boecker Niagara cloud, available through the company’s web app. The sensor configurations are customizable and placed on both the body and bearings of the vibrating screen.

Haver & Boecker Niagara’s accompanying app displays all the information in an easy-to-use portal, providing users a full overview of equipment in real time. They can access detailed information specific to each of the body and bearing sensors in order to identify the equipment’s operating condition and health of each component.

WHY?

PULSE CM WILL HELP YOU PREDICT COMPONENTS & DRIVE STRUCTURAL FAILURE

Lothar Gillenkirch, Head of Service Department, Germany

YOUR SERVICE PLAN

Never was it so easy to increase your production – Order your Niagra CM Pulse Service Plan Now!

YOUR BENEFITS ARE ENSURED

No matter what your industry is, Pulse Condition Monitoring will bring the best analysis performance of your equipment:

- advanced algorithms

- accurate measurements & forecasts

- easy-to-understand information

Let us show you what Pulce Condition Monitoring can do for your business!

Want to know more about the new Niagara Pulse Condition Monitoring?